Factory-fresh diamond-cut finish in one session

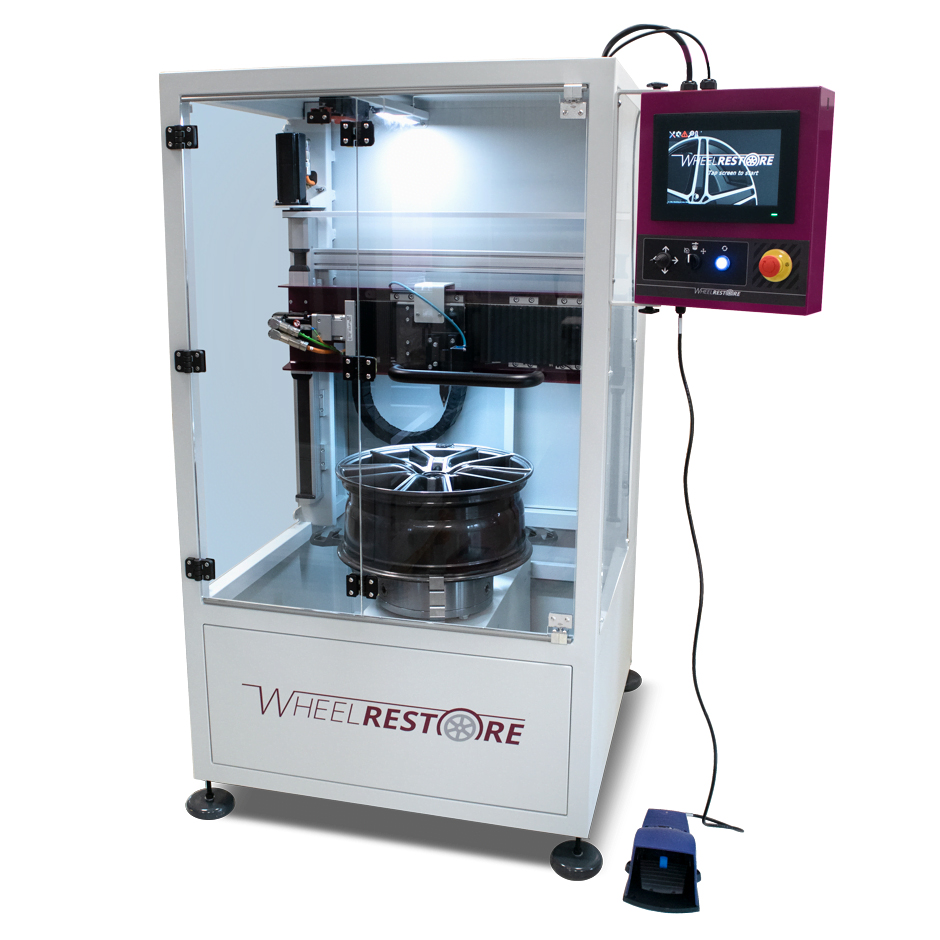

A compact, workshop-ready wheel lathe with automated laser probing and a guided touchscreen—so technicians produce repeatable, OEM-grade finishes without removing the tire.

- Repair with or without the tire—faster workflow

- Laser probing maps rim profile for precise, repeatable cuts

- Step-guided touchscreen software—built for wheel repair

- Wheel library; supports most wheels up to 30”

Compatible with the vast majority of OEM wheels you’ll see day-to-day.

Fast turnarounds—even on busy days and seasonal changeovers.

Reliable volume without adding headcount or floor space.

Easy to install; workshop-ready from day one.

Dealerships & groups

Capture wheel cosmetic work in-house and return factory-level finishes without shipping delays.

Wheel & tire centers

Offer same-day diamond cuts—keep the tire on, ideal for seasonal changeovers.

Bodyshops & smart-repair

Shorten cycle times with step-guided software in a compact, workshop-ready unit.

≤ 30” Wheels

Compatible with most vehicle wheels in APAC markets.

Laser Probing

Auto analysis & curve mapping for consistent surface finish.

Touchscreen UI

Purpose-built interface with step-guided operations.

Wheel Library

Save and reuse profiles for repeat customers & fleets.

Laser probing analyzes the wheel shape—so cuts are spot on

The 3D probe scans the rim and feeds the cutting software to match thousands of wheel designs and sizes—then hands the settings straight to the cutting step.

Automation removes guesswork and speeds up operator training.

How it works

1) Mount

Clamp the wheel—tire on or off. No bead breaking required for most jobs.

2) Probe

Laser scans the rim profile while rotating; software maps the curve.

3) Cut

Guided parameters ensure a consistent diamond-cut finish.

4) Verify

Save the profile to the library for repeatable results next time.

Quick guide • 1:09 • Real UI workflow

Built for real workshops

- ✓Digital optimization software package

- ✓Wheel profile storage—wheel library

- ✓Automated laser probing while spinning

- ✓Fully CE compliant, compact footprint

Repair with or without the tire

Unique in market: process rims without removing tires. Save time during seasonal changeovers and slot work into quieter periods.

Key specifications

Up to 30″

12” touchscreen with step-guided workflow

Laser-based curve mapping

CE certified

*Confirm electrical and footprint details with our team for your site.

Footprint & utilities

- ✓Compact, workshop-ready footprint

- ✓Standard single-phase power (confirm site)

- ✓Dust control & safety interlocks

What’s included

Core unit with touchscreen control.

Automated curve mapping.

Save & reuse profiles for repeat work.

Guided set-up and cutting.

On-screen steps and presets.

M&H Group installation & assistance.

Compliance & safety

Built to CE standards with safety interlocks, protective enclosure and clear on-screen prompts for each step.

FAQ

Do I need to remove the tire?

No—WR-DCM3 can process rims with or without tires, speeding up turnaround and allowing work in quieter periods.

How many wheels per hour/day can we repair?

On average you can restore 4+ wheels per hour, roughly 25–30 per full day, depending on damage and operator experience.

How long does a single repair take?

About 15 minutes per wheel from mount to finish.

What power supply does it need?

Runs on standard single-phase 110/230V and plugs into a normal socket. The unit is pallet-jack movable.

How many times can a wheel be diamond-cut?

Typically 2–3 times, assessed case-by-case to protect structural integrity. Laser probing helps minimize material removal.

How much training is required?

The UI is step-guided. Most technicians become confident after about one day of training.

What completes a full diamond-cut setup?

Common complements: wheel straightener + automatic wheel paint machine (clear coat). Optional: tire bead breaker, spray booth.

What’s the maximum wheel size?

Up to 30″.

Is it CE compliant?

Yes—fully CE compliant.

Is it mobile-ready?

Yes. Compact, quiet and van-installable; can run from a standard socket.

What size is the touchscreen?

12″ touch display.

Do you provide support resources?

Yes—online Service & Support platform with manuals, e-learning and a 24/7 ticket system.